Three decades ago, our founder invented the technology behind 3D printing – and we’ve been at the forefront of innovation ever since.

Our expertise helps leaders in industries like aerospace print more complex parts using certified materials, while cutting costs. And with smart software for rapid design iterations and functional prototyping, Stratasys helps you innovate faster than ever before.

Aurora Flight Sciences together with Stratasys took on an ambitious project: to build a jet-powered, thrust vectoring, blended wing body, remotely piloted aircraft. Pushing the power of additive manufacturing to new heights, Aurora optimized design to create a lightweight, stiff structure made up of 80% 3D printed parts. The result? A flight ready aircraft, that put an idea in the sky.

We put our thermoplastic materials through rigorous quality and reliability tests. Try Antero 800NA with its high strength and chemical resistance – trusted by industry leaders in aerospace. Or Nylon 12CF for tooling that brings simplicity and strength to the demands of the production environment. No matter what you’re making, we’ve got the material to fit your vision.

Functional design testing and industrial production demand very special materials. Our Nylon 12CF material is just that: a carbon-fiber reinforced thermoplastic. It matches metals for strength and stiffness, yet it’s incredibly light – delivering a final product that’s strong, cost effective and less complex to produce.

Need something impervious to high temperatures and chemicals? Our industrial strength Antero 800NA material is designed for high-intensity aerospace projects – it’s also unbeatable for parts that need low outgassing properties. Paired with FDM technology, it avoids the waste and high costs of subtractive manufacturing using bulk PEKK material.

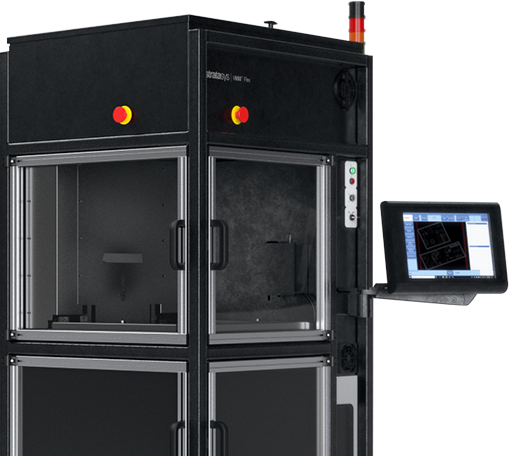

Our new V650 Flex 3D Stereolithography printer is built for high-spec innovation. Over four years we ran the V650 Flex for more than 75,000 hours to create 150,000 parts. The result? Consistent smooth-surfaced prototypes, master patterns, and large concept models, all printed at new levels of speed and precision. Each time, every time.

3D printing helps you work smarter and faster, cutting time-to-revenue through fast-tracked design, testing and build. We’ve solved the challenges of innovation, delivering rapid iterations, accurate prototypes, and reduced downtime. All to help you shorten the process and improve your bottom line.

Lower production costs and lead times

Test concepts and functionality quicker

Easily adjust and reprint your designs to perfect product